Before 2008, when TPMS became mandatory, valve stems were replaced as part of replacing every tire. Valve stems are designed for one-time-use components and require replacement whenever a new tire is mounted.

Today we use rebuild kits to service the valve stem and ensure that they don’t leak or suffer from corrosion due to road salt, harsh weather conditions, and normal wear and tear.

What Is TPMS Service?

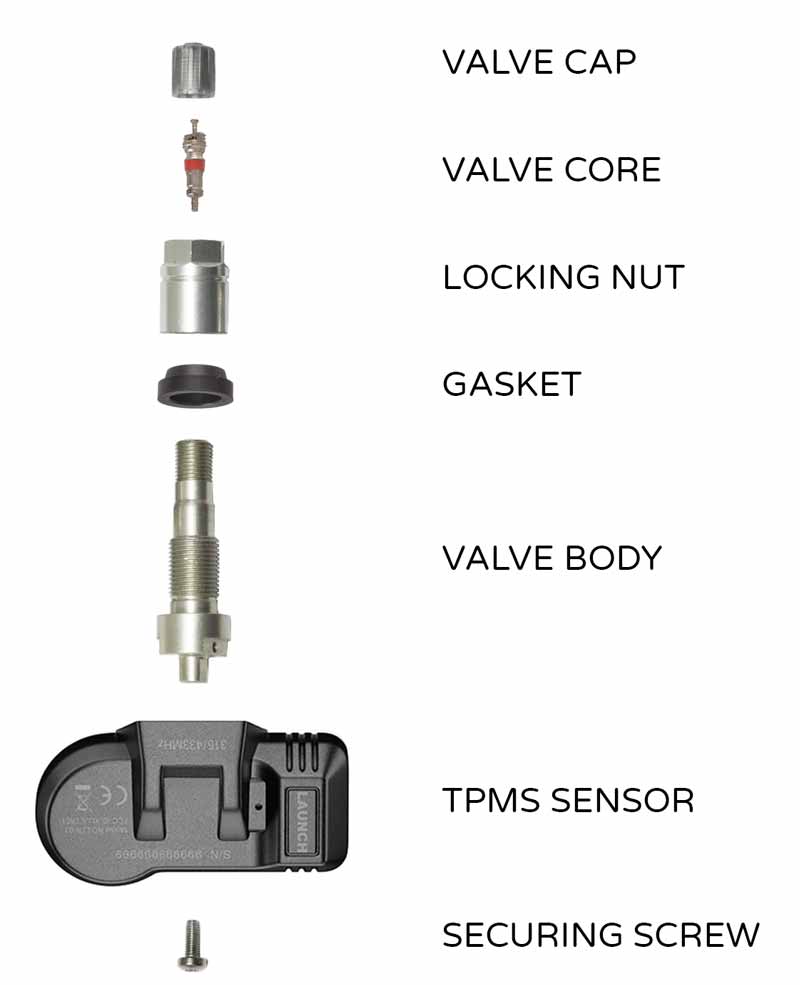

A TPMS service is the installation of a tire pressure monitoring system service kit. A service kit, also known as a rebuild kit, includes:

- Seals

- A valve core

- A locking nut

- Any other additional hardware required to install a tire air pressure sensor

There is some confusion surrounding these rebuild kits, so we’ll answer the most common questions about their use and how necessary they are.

Let’s take a closer look.

What Is A TPMS Rebuild Kit?

A TPMS Rebuild Kit is a service kit for the valve stem of your Snap-In or Clamp-On style TPMS sensors. These two styles of TPMS sensors are the most common and used on most vehicles.

TPMS Rebuild Service Kit Example

These rebuild kits include the seals and mounting hardware used to attach the stems to the wheels and the tire pressure sensor. The kits are meant to address leaking valve stem seals and corrosion on the threads of the mounting hardware.

These service packs include a new valve core and a valve stem cap. The kit does not include the actual valve stem or a TPMS sensor.

TPMS Service Vs TPMS Sensor Replacement

Tire pressure sensors eventually need replacement but generally last between 7 and 10 years. Though it’s common to see some begin to fail around the 5-year mark.

The valve stems connected to the pressure sensors are designed to be replaced while you are replacing tires. They are one-time-use components and are not meant to last as long as the sensors.

TPMS service includes the hardware necessary to replace all potential points of failure with the valve stem to ensure that the tires remain leak-free. This helps the tires to withstand the harsh weather and conditions of another 50 thousand miles or however long your tires will last.

Is TPMS Service Necessary?

TPMS service isn’t technically necessary, but it is highly recommended. It’s a service that is often questioned. This is because the naming convention used for this makes it sound more involved, and when someone realizes it’s essentially reinstalling the valve stems with new seals, they may feel like they were misled.

This is my assumption based on my experience. Whatever the reason for the skepticism, it is a service you should have performed.

Before the Tread Act required the inclusion of a tire pressure monitoring system on every passenger vehicle sold in the United States, replacing valve stems at the same time as replacing tires was standard practice.

Due to the inclusion of air pressure sensors being incorporated into the base of the valve stems for most TPMS systems, this practice has switched to the use of rebuild or service kits.

TPMS Service Cost?

A TPMS Service Kit and the labor to install the kit should be minimal. The rebuild or service kit should only cost a few dollars per wheel, and the labor should reflect the tire shop’s hourly rate for a few minutes of installation time for each wheel being serviced.

Clamp-In Vs Snap-In TPMS

There are several different types of TPMS sensors, but the most common types are the Snap-In and Clamp-In varieties:

Snap-In

Snap-In TPMS sensors are rubber valve stems that look very similar to older-style valve stems that didn’t have TPMS sensors at the base of the stem.

They’re excellent air pressure sensors but lack any adjustability and some durability found in clamp-in-style sensors. Also, when servicing at Snap-In TPMS sensor, the entire valve stem is replaced instead of using a service kit. However, the replacement rubber valve stem may be referred to as a Snap-In rebuild or service kit.

Clamp-In

Clamp-In TPMS sensors are metal valve stems that are more rugged and provide more adjustability to allow them to fit more wheel types better. You’ll likely see these more regularly on premium cars and trucks or those with lower-profile tires.

Instead of all valve stem components being integrated into one part, clamp-in valve stems include multiple pieces that fit together. These parts are not meant to be reused due to their exposure to harsh weather, and the effects corrosion can have on the metal threads and seals.

Resources

Below are some links you may find helpful when learning about tires

Final Thoughts

Your tire pressure monitoring system is important to maintain. Replacing the mounting hardware and seals associated with your TPMS sensor each time you have new tires mounted onto your car or truck will help ensure you don’t have slow leaks develop or issues with damage to the valve stems.

While you can skip this service if you desire, it is recommended and a small price to pay for a little extra insurance against flat tires.

Good luck and happy motoring.