In 2007, tire pressure monitoring systems became mandatory for all vehicles sold in the United States. This has been great for safety but these systems do add some complexity to your vehicle.

How Does TPMS Work?

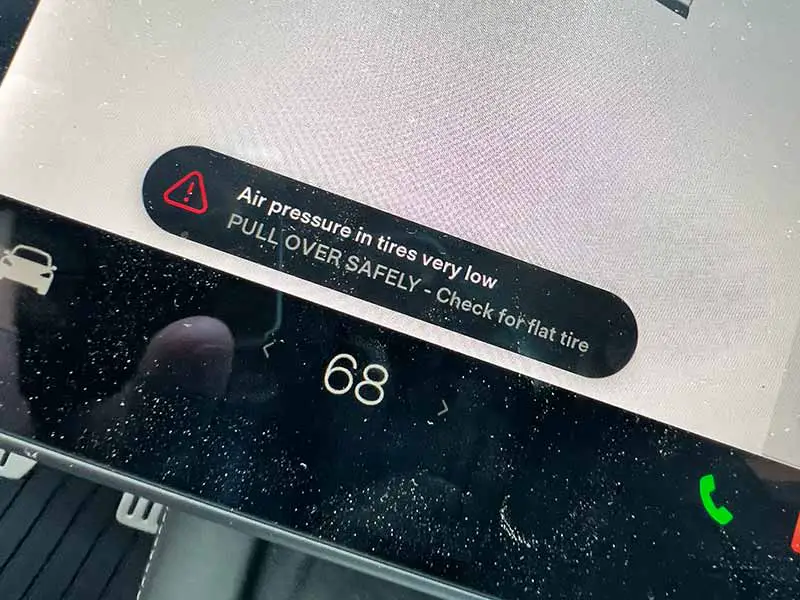

Tire pressure monitoring systems monitor air pressure (directly or indirectly) and alert the driver when the pressure drops by 25% or more than the target tire pressure.

It does this by displaying a low-pressure warning light on the dashboard.

- Direct TPMS uses battery-powered sensors in each wheel to directly measure air pressure in each tire and wirelessly transmit that information to the TPMS computer.

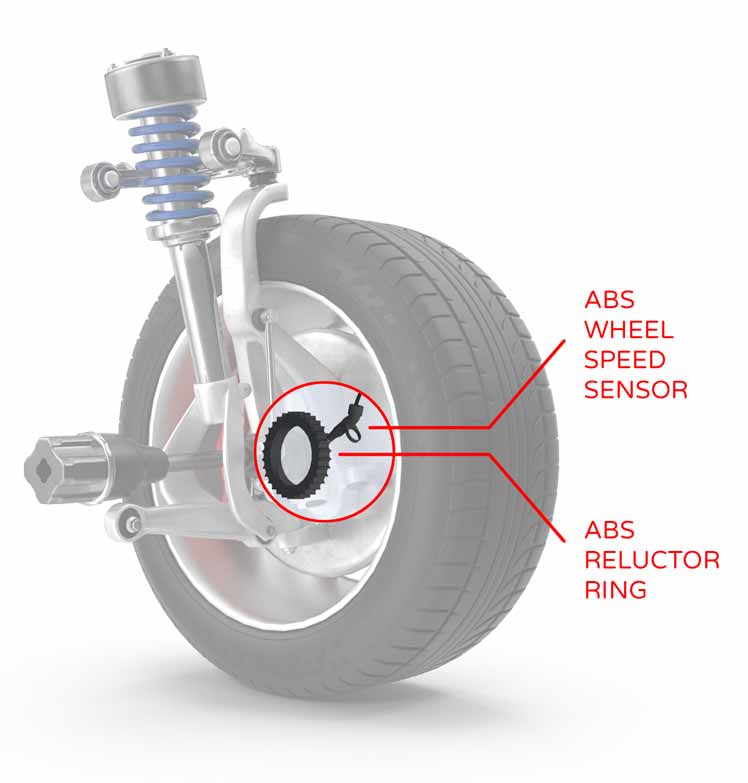

- Indirect TPMS uses the same wheel speed sensors used by the anti-lock braking system to measure differences in the speed that each tire spins to estimate when tire pressure has dropped significantly.

Your vehicle’s recommended tire pressure is important not only for extended tire life but to prevent tire failure such as a catastrophic blowout.

How do these systems work with spinning tires that take so much abuse? How do they communicate with your car or truck? And how do the sensors get their power?

Let’s take a closer look.

TPMS Light

When the low tire pressure warning light on your dashboard comes on it means that one of your tires has lost 25% or more of the vehicle manufacturer’s recommended air pressure.

To turn the low tire pressure warning light off, you usually only need to add air to the tire or tires that are not up to the proper amount of pressure. Often you will need to drive for a period of time before the sensors can detect the pressures have returned to the appropriate amounts.

If the tire pressure monitoring system light is flashing, it usually means that there is a problem with the system in some way. There could be a damaged sensor, a sensor has lost its connection with the TPMS computer, or a battery has died in one of the sensors.

Direct Vs Indirect TPMS

There are two different types of tire pressure monitoring systems – Direct and Indirect. To as simply as possible explain the difference between these two systems, direct tire pressure monitoring systems uses sensors in each tire to measure air pressure. An indirect tire pressure monitoring system uses wheel speed to essentially make an educated guess about when a tire is low on air pressure.

How Does Direct TPMS Work?

Direct TPMS works by installing a dedicated tire pressure sensor inside each tire that wirelessly communicates with the tire pressure monitoring system computer. Each battery-powered sensor will usually last up to 10 years or more.

To help extend battery life, each sensor is usually powered down when the tires aren’t spinning. This is why you may top up your tire’s air pressure and the tire pressure warning light is still lit on your dash. You’ll need to drive a short distance to activate the sensors and have them update the pressures to the TPMS computer.

Each sensor has a unique ID that is registered to the TPMS ECU so that the system can differentiate between the different sensors and understand which sensor is located at which position around your vehicle.

This means that every time your tires are rotated or you have a need to move a wheel assembly with a sensor from one position to another around your car or truck you will need to resynchronize the sensors with the system so they can accurately report the pressures of the appropriate tires.

Pros

- Very accurate

- Ability to monitor the pressures of each tire

- Can also be used to track spare tire pressure

Cons

- More complex

- More expensive

- Some systems require hardware for sensor synchronization

- Sensors will eventually fail either due to damage or a dead battery

Types Of Direct TPMS Sensors

There are several different types of sensors that direct TPMS systems can use. Let’s review each type and explain the differences.

Snap-In

Snap-in sensors are a very common type of sensor. They are incorporated into the valve stem and snap into the valve stem opening in your wheel.

Most passenger cars and trucks will use this type of sensor.

Clamp-On

Clamp-on sensors are very similar to snap-in-style sensors. They are incorporated into the valve stem like the snap-in sensor, but they are more durably constructed, using mostly metal, and are adjustable to better fit aftermarket rims.

These differences usually cause clamp-on sensors to cost a bit more than the snap-on style. It’s common to find them used on more premium vehicles.

Band Clamp

Band clamp pressure sensors are strapped to the barrel of the wheel. They are usually mounted near the middle of the barrel and aligned with the valve stem or 180º opposite of the valve stem.

This style sensor has become fairly unpopular, in part due to the varying barrel hump designs and low-profile tires.

Valve Cap

Valve cap sensors are usually inexpensive aftermarket sensors that come with an inexpensive aftermarket system. You will not find one of these systems installed on a new car or truck.

The fact that a valve cap can easily be removed is a benefit for easily knowing where each sensor is located, although they can be easily lost or stolen.

Valve Cap TPMS Sensor Example

How Does Indirect TPMS Work

Indirect TPMS uses the wheel speed sensors used by the anti-lock braking system and traction control to monitor wheel speed and make educated guesses about air pressure based on changes in the speed of the wheel assembly as it spins when compared to the others.

This type of tire pressure monitoring system is significantly less complex which means that it is also less expensive for vehicle manufacturers to install in their vehicles. It also requires no real maintenance on the part of the vehicle owner since there are no pressure sensors that need to be resynchronized or replaced.

This makes the process of replacing or rotating tires simpler since there are no steps involved with the tire pressure monitoring system.

ABS Wheel Speed Sensor Example

Unfortunately, as you may be able to guess, estimating when a tire may have lost pressure is not nearly as accurate and it can’t report actual pressures for individual tires. This type of system is also prone to false alerts in some circumstances.

In general, indirect TPMS is very reliable for alerting you to a low tire pressure situation that could be significantly problematic. This is adequate and addresses the government mandate well.

Pros

- Simple system

- Requires no real maintenance

- Able to reliably alert the driver to a serious air pressure situation in most circumstances

Cons

- Can’t actually measure air pressure

- Can cause false alerts or fail to detect issues in some rare situations

- Can’t reliably inform you which tire has lost pressure

Tire Pressure Monitoring System Reset

Direct TPMS systems don’t always have a reset button. Usually, you can simply adjust your tire pressures to the proper tire pressure and this will clear the low-pressure light after you have driven for a period of time.

If your direct TPMS has a reset button it is usually meant to set the baseline pressure which it uses as the pressure to compare against. This way you can set the pressures to something other than the vehicle manufacturer’s recommended tire pressure if you need to do so for any reason.

TPMS reset buttons are used on indirect tire pressure monitoring systems to tell the system to recalibrate itself. Different vehicle manufacturers will have variations on the complete procedure to reset your TPMS, however, the reset button is usually a common element used in most systems.

You’ll want to check your owner’s manual for the unique steps your vehicle manufacturer requires for resetting your TPMS system. Some variations may be whether the car or truck must be started or not, how long you may need to press and hold the reset button, or whether you need to drive a certain distance before the process is complete.

Also, the reset button has no standard location. The button could be on the console, in the glove box, to the left of the steering wheel, integrated into the infotainment system, or even actually not a button at all and requiring an elaborate sequence of toggling other buttons or knobs in lieu of a dedicated button.

Where Are Tire Pressure Sensors Located?

Indirect TPMS uses the wheel speed sensors on your car or truck to estimate if there is a substantial air pressure drop. There are no actual tire pressure sensors used in this type of system. Indirect TPMS relies on the use of the antilock braking system’s wheel speed sensor which is mounted in the hub of each wheel.

Direct TPMS sensors are actually mounted inside the tire and communicate wirelessly to the TPMS computer. Usually, the sensors are at the base of the valve stem just inside the wheel. Some systems will have the sensor strapped to the middle of the barrel of the wheel. Sensors strapped to the barrel are much less common these days.

How Do TPMS Sensors Get Power?

TPMS Sensors have batteries in them that are sealed to protect them from water and other harmful liquids that could damage the battery or electronics within the sensors.

The sensors typically have a lifespan of 7 to 10 years and the entire sensor usually needs to be replaced since the battery usually can’t be easily removed and replaced.

It’s usually recommended to simply replace the sensors once the battery finally dies. It would be smart to replace all four sensors (or five if you have a spare tire with a sensor) when one battery dies since the others will likely die soon afterward. This will save you multiple trips to your local tire shop.

How Does TPMS Know Which Tire Is Which?

Indirect TPMS usually doesn’t indicate which tire is the problem tire since it is only measuring differences in the wheel speeds. If it senses a difference it will alert you by turning on the low tire pressure light on your dashboard or center console. You’ll need to check each tire and compare it to the manufacturer’s tire information sticker on the driver’s door jamb.

Direct TPMS measures the pressure of each individual tire with unique sensors that broadcast their pressures to the system. Each sensor needs to be registered to the system to indicate which position it is located in.

Registering individual tire pressure sensors to the TPMS usually involves the use of a programming tool. This needs to be done each time your tires are rotated or any time you have a need to move one wheel assembly to a different position.

Resources

Below are some links you may find helpful when learning about tires

- What is TPMS & how does it work? – Bridgestone

- What you need to know about tire pressure monitoring systems – Edmunds

Final Thoughts

Your tire pressure monitoring system is a fairly sophisticated bit of technology. It does an amazing job of reducing your safety risk by keeping an eye on your tire’s pressure day in and day out for several years at a time.

Good luck and happy motoring.