Metal and rubber valve stems are referred to as Schrader valves. Schrader valves have a removable valve core that uses a spring to keep the valve closed when not held open.

Each is an excellent choice but has unique properties that make them better for different uses.

Metal Valve Stems Vs Rubber

Rubber valve stems are superior to metal valve stems at their primary purpose – preventing leaks while allowing you to pressurize passenger car and truck tires. Due to their flexibility, they are much better for off-roading.

Metal valve stems are more attractive and capable of doing an excellent job but are less durable and require more frequent replacement.

While rubber valve stems may be superior, there are times when you may be better suited to use a metal valve stem.

Let’s take a closer look.

Metal Valve Stems

Metal valve stems have gained popularity mainly due to their good looks. Aluminum valve stems will make a slight difference in the look of your car or truck.

Generally speaking, metal valve stems are better for extreme speed and air pressure use but are less durable due to their lack of flexibility and shorter seal lifespan.

Most passenger vehicles don’t have any genuine need for the speed or pressure advantages that metal valve stems provide. Rubber stems are more than capable.

But if you prefer the looks of metal valve stems, you need more than the downsides to stop you from using them. They are more than capable of performing the job well. Just be sure to replace them every time you have your tires replaced.

Pros

- Considered more attractive

- Able to handle high speeds better (130 mph+)

- Able to handle high pressures better (200 psi max)

Cons

- More prone to thread corrosion

- More likely to break if hit

- More prone to leaking over extended periods

- Torque requirements for the locking nut complicate the install

- More expensive

Rubber Valve Stem

Rubber stems are superior to metal stems in every way that matters to the average passenger vehicle. They don’t look as nice, but rubber valves will last longer and take more abuse than metal ones.

Rubber valve stems are also much better for off-road vehicles since rocks and debris will be far less likely to cause one to break.

If you could care less about aesthetics, you should choose rubber valve stems. Some TPMS sensors have limited adjustability when paired with rubber valve stems, making them difficult or impossible to fit on some wheels.

As product manufacturers continue to evolve their product lines, we see more rubber valve stems with adjustable angles for TPMS sensors.

Pros

- Considered less attractive

- Not ideal for applications that exceed 130 mph

- Not suitable for applications that exceed 100 psi

Cons

- Fewer points of failure

- Simpler installation

- Able to flex without breaking

- Sealing abilities last longer

- Less expensive

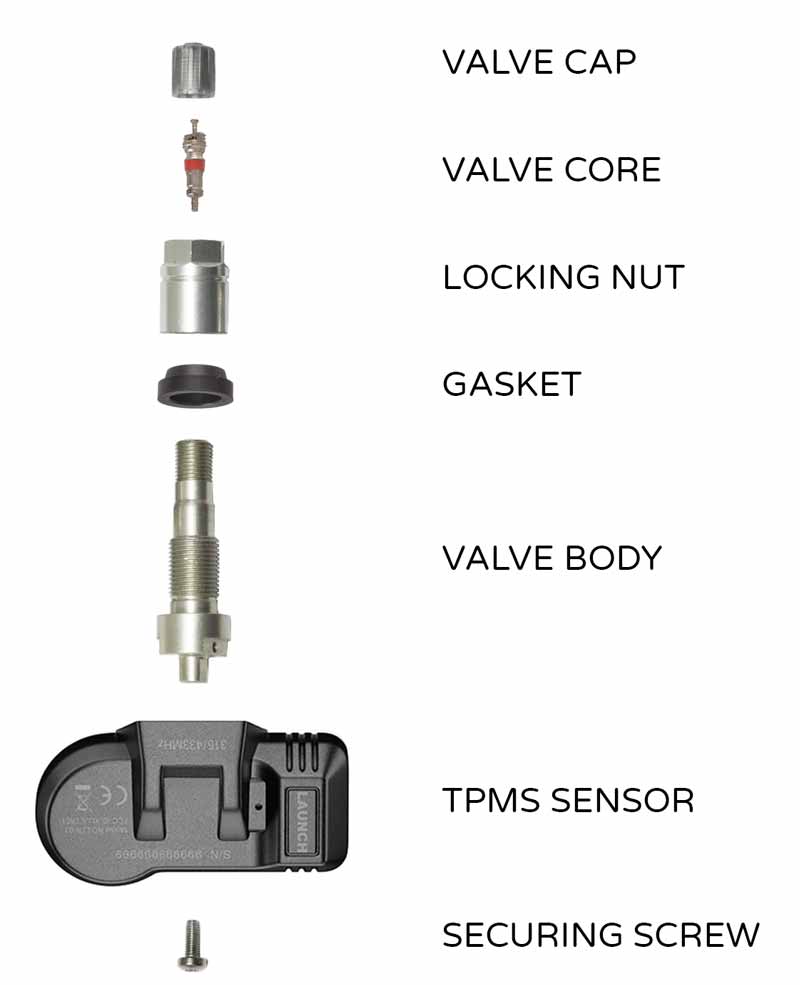

Parts Of A Valve Stem

Both metal and rubber valve stems share many parts, but metal valve stems are more complex. The following is a breakdown of each component, its description, and whether it is used in metal valve stems only or both metal and rubber valve stems:

Valve Cap (Metal & Rubber)

A valve cap is a small, removable cap that screws onto the top of the valve stem to protect the inner parts of the stem from dirt and debris. They come in both metal and plastic designs. Metal designs are considered more attractive. However, they can be prone to corrosion and seizing in some climates.

Valve Core (Metal & Rubber)

This small, spring-loaded device controls airflow into and out of the tire. It is located inside the valve stem and can be removed using a unique tool. A stem with this type of valve and removable core is called a Schrader valve.

Locking Nut (Metal Only)

The locking nut is a nut that is used to secure the valve stem to the wheel of a car or truck. The locking nut is typically made of metal and has a unique threading pattern that makes it resistant to loosening due to vibration or other forces.

To install a locking nut on a metal valve stem, you would first thread the nut onto the end of the valve stem and then tighten it down using a wrench or other tool. Once the nut is tightened down, it should hold the valve stem securely in place, preventing it from coming loose or falling off.

Gasket (Metal Only)

The valve stem gasket fits over the valve stem body and underneath the locking nut. It creates an air-tight seal between the valve stem and the wheel’s barrel.

Valve Body (Metal & Rubber)

The valve body is the main structure of the valve stem. It is designed to accept the other parts of the valve stem. It is also the main conduit through which air is meant to flow in and out of the tire during pressurization or depressurization.

TPMS Sensor (Metal & Rubber)

All passenger vehicles since 2008 have been required to have a tire pressure monitoring system (TPMS). While not all systems incorporate sensors into valve stems, most do.

The sensor is attached to the base of the valve stem inside the tire and wheel and wirelessly communicates to the TPMS computer to report the current air pressure inside the tire.

TPMS sensors use batteries sealed inside the sensor housing for power and have a limited life span, typically between 7 and 10 years. These batteries are not usually replaceable, and the sensor is expected to be replaced when the battery dies.

Securing Screw (Metal & Rubber)

The most common method of attaching the TPMS sensor to the valve stem is a securing screw. This tiny screw secures the sensor to the base of the valve stem.

Removing the sensor from the stem and only replacing it is possible, but replacement of valve stems is recommended whenever a tire is serviced to ensure a good seal.

Frequently Asked Questions

The following are some common valve stem-related questions that we’ve answered for you:

How Long Do Valve Stems Last?

Generally, valve stems last 7 to 10 years, but this can vary quite a bit. Rubber valve stems will easily meet or exceed this life span due to their superior sealing abilities.

Metal valve stems have shorter life spans than rubber valve stems. The reason is that the seals are more prone to leaking with age. For this reason, metal valve stems are suggested to be replaced whenever your tires are removed, such as when purchasing new tires.

It would be best if you replaced even rubber valve stems regularly to help avoid leaks and other valve stem-related problems.

Why Do Valve Stems Leak?

Exposure to harsh weather and age are the primary causes of seal failure in valve stems. The seals used in metal valve stems are more prone to failure but should still last a long time.

Damage can also cause a rubber or metal valve to leak. Metal stems are a poor choice for off-road vehicles since rocks and other debris can easily cause metal stems to snap off. Rubber valve stems can become cut or torn but tend to be able to take more abuse than a metal valve stem.

Are Valve Stems Universal?

Passenger cars and trucks all use Schrader-style valve stems, and they will all be of the rubber or metal variety. There are minor variations between valve stems, but it is reasonable to consider them a universal design.

Are Valve Stem Caps Universal?

No matter whether you have rubber valve stems or metal valve stems, valve stem caps will all have the same thread pattern and are interchangeable between all passenger vehicle valve stems.

Is The Valve Stem Part Of The Tire Or Rim?

The valve stem is neither a part of the tire nor the wheel. It is its own component. It does not come with the purchase of a tire or wheel and is a separate purchase. While you may not realize it, valve stems are usually included as an additional fee when purchasing new tires.

Resources

Below are some links you may find helpful when learning about tires

- Info: What is the advantage of metal valves – TuningBlog.eu

- Rubber vs. aluminum valve stems: Which do you choose? – Tire Review

Final Thoughts

What’s better, metal or rubber valve stems? The metal ones are very pretty and will do a good enough job that you shouldn’t worry about which is best. A rubber stem will be a better choice if your decision is based only on function.

I run metal valve stems on my car and stand by them. They’re not technically better, but I prefer them, and I suspect most people who are into cars and trucks will too.

Good luck and happy motoring.